History of the Hydra complex

Development, production and implementation of Hydra complex was started in 2000. Since then, several generations of the complex have been produced, its characteristics are constantly being improved, and its application areas are expanding.

Hydra is a registered trademark owned by the company "Screen-Co Ltd".

- Generation 1 (Hydra 1)

- Generation 2 (Hydra 2)

- Generation 3 (Hydra 3)

- Generation 4 (Hydra 4)

The developed complexes have a number of features:

- The construction of the sonar is based on the principles of digital formation and signal processing, which allowed to improve significantly the quality of the received information;

- In addition to the tonal sounding signal, a complex sounding signal with linear frequency modulation (LFM) is also used, which allowed to increase the sonar noise immunity, its energy potential and, as a consequence, to increase the range several times while maintaining high resolution;

- The principle of interferometer is the basis for measuring the bottom relief by the sonar. Unlike multibeam echo sounders, interferometer allows to receive from one system simultaneously acoustic image of the bottom and its relief without errors of combination. Compared to multibeam echo sounders, which use several dozen reception channels to receive echoes, the Hydra sonar uses only a few channels, which significantly simplifies the hardware part of the complex. This implies a number of advantages in price, reliability, dimensions against the background of high resolution and no errors when combining the information of two or more systems.

- The complex is built as a mobile system. Light weight and dimensions allow mobile deployment of the complex on vessels of any displacement, starting from a rubber boat.

Complexes of generations 3 and 4 are self sufficient and allow to solve a wide class of practical problems in the interests of various sectors of the economy without the use of other acoustic systems :

- engineering and geological surveys at underwater polygons

- search and rescue operations

- preparatory works for the construction of underwater structures

- scientific, ecological, engineering monitoring of underwater objects, etc.

|

|

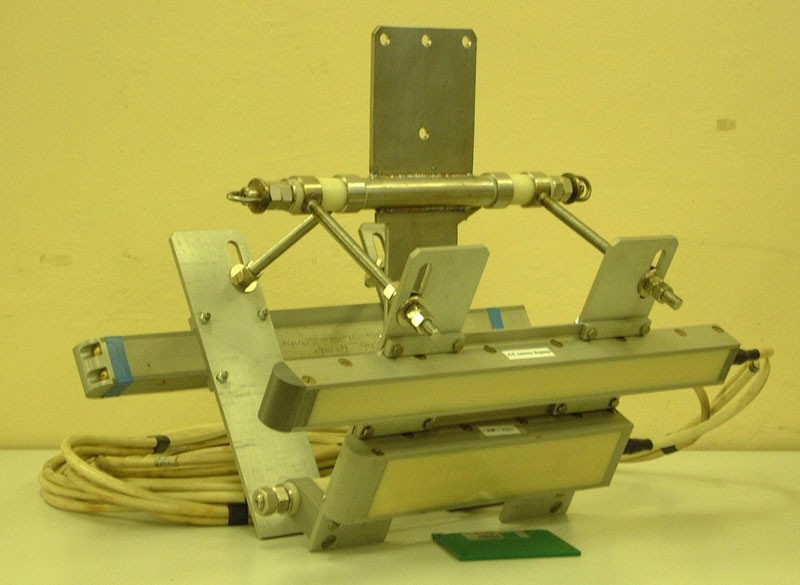

| Hydra antenna unit 1 |

The Hydra complex of the first generation (Hydra 1) was developed in 2000 and is still successfully operated in the RJSC UES system to assess the condition of dam reservoirs of hydroelectric power plants, to identify the degree of erosion of the bottom in places of water fall.

The complex is made in the configuration of a double-Board ISSS with operating frequency of 250 kHz. Structurally it is a computer with an installed receiver board, an antenna unit and a power amplifier.|

|

|

Hydra2 receiving and transmitting unit (Euromechanics 3U housing) |

The complex Hydra of the second generation (Hydra 2) was developed in 2002 and was already a monoblock in the design of Euromechanics 3U 19", which was connected to a computer via Ethernet 10 Mbit.

This sonar has been used successfully and repeatedly by investigators of the Prosecutor General's office of the Russian Federation to search for bodies under water. In addition, with the help of this sonar, several works were carried out, including control works to assess the laying of an oil pipeline on the Baltic sea in the area of Zelenogradsk.

|

|

| Hydra 3 transmission and reception unit (SSS, Euromechanics 3U housing) |

The third generation Hydra complex (Hydra 3) was developed in 2005. Its differences from the second generation are: support of the configuration of the PPF, reducing the size of the receiving and transmitting unit (RTU), the use of an Ethernet line of 100 Mbit.

The third generation of sonar is a hydroacoustic complex-transformer. The hardware composition of the complex is recruited from unified modules for specific tasks in various combinations: depth sounder, side-scan sonar, interferometer and a profilometer. The frequency range of each system, power supply option, antenna mounting, etc. is determined depending on the tasks to be solved.

|

|

|

| Antenna Hydra 3 (SSS) | Hydra 3 receiving and transmitting unit (RTU, Euromechanics 3U housing) |

|

|

|

Hydra4 receive / transmit unit (Prof version) |

Currently, the latest (fourth) generation of the complex - Hydra 4 - has been developed and put into mass production.

Hydra complex of the fourth generation was developed in 2008 and is radically different from previous generations.

The use of modern innovative technologies and solutions, the development of own production of antennas, allowed to reduce significantly the size and weight of the complex, increase its potential.

The main differences Hydra 4 from the previous generation:

- significant reduction in size (5 times) and weight (8 times)

- use of built-in sensors

- possibility of simultaneous operation of several complexes on one vessel

- connection of external sensors to RTU ( receive / transmit unit )

- switching modes of operation of the complex without stopping

- Design of the RTU in accordance with IP67

- Reducing the number of cable network connectors used to simplify connection

- fully updated version of the base kit SOFTWARE with enhanced features and interface

|

|

|

|

|

|

Receiving and transmitting unit And SSS hydra4 antenna unit (Light version) |